Cam Design Guide for Weber Carbs

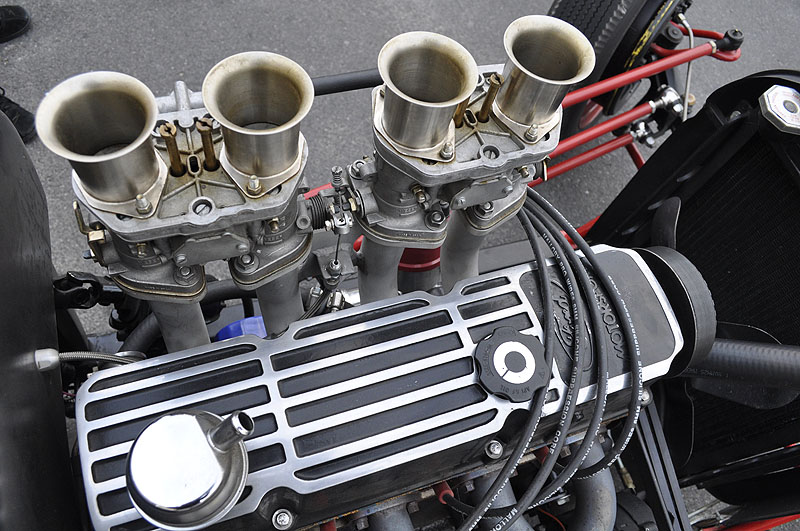

If you’ve visited MyRideisMe.com before, you know I have a 27 Ford Roadster with a fairly hot 2.3L Ford four cylinder that’s better known as a “Pinto Motor”. I’ve got a not-so-cool problem with the Weber 44 IDF induction setup right now though…

If you’ve visited MyRideisMe.com before, you know I have a 27 Ford Roadster with a fairly hot 2.3L Ford four cylinder that’s better known as a “Pinto Motor”. I’ve got a not-so-cool problem with the Weber 44 IDF induction setup right now though…

When I get into the throttle, not that I’d ever do that, I get a misting of fuel over the top of the carbs. OK, it’s less of a mist than a toxic ozone killing cloud of gas vapor. (I’ll commute tomorrow to make up for it!). I owe you a video of this, before and after.

So what I’d do? I knew Inglese Induction Systems are the experts. Inglese has been making intakes for this setup for a long time so they must know what’s happening and how to fix it. Even more cool? Inglese is now owned by the Comp Performance Group that also owns, Comp Cams. I’ve always had great success with Comp Cams in my Ford V8’s and my pops has been really happy too. Having 2 great reasons, I called over to Comp Cams.

I spoke to Jay over in Comp Cams tech support. Jay knows his cams and was super polite. I asked him to write down what he was thinking for my set up and this is what he said:

When doing cams for engines equipped with Weber carburetors, it’s imperative that you keep overlap of the cam reduced to that similar of what would be acceptable in an OEM injected throttle body type engine. The reason for this is the Weber carburetors are rather finicky as to what they like at idle and part throttle operation, and really prefer a strong/consistent vacuum signal.

When using long(er) duration cams, and/or tight (110 or less) lobe separation angles, the Weber carbs are bad about “vaporing” fuel out of the top of the velocity stacks, (as in your application). Reducing the length of duration, and using a quicker ramp profile on the cam lobes, naturally reduces overlap; as does widening the lobe separation. The combination herein provides a more consistent vacuum signal, flatter torque curve, and should (in your case) promote some low end throttle response and torque.

What I’ve come up with for you is a solid lifter cam that will be a 226 @ .050 duration on the intake; and 236 @ .050″ on the exhaust. More difference between the intake and exhaust durations (aka “split”) should help to burn some of the excess gaseous vapors that would otherwise continue to travel back up your intake manifold runners, and linger above the carbs. I’m going to suggest that we us a 112 lobe separation angle (as opposed to the 110) you have now. This, along with the change (reduction) in duration, should get the torque to come on sooner and make the car more fun to drive on the street; and in a more user friendly RPM range.

These cams also require nitriding (p/n 1-111-1) service as well.

So I asked, What’s with the Nitride treatment? It’s kinda pricey…

Nitriding over head cams is absolutely necessary. It’s strengthens the cam which has the constant load pressure associated with the follower/rocker and spring combination. The reason it’s become so necessary now (rather than long ago) is a two part answer:

Lobes have gotten far more aggressive (this doesn’t necessarily mean BIGGER); they have much faster ramp rates, more dwell time at max lift, etc. Secondly, the “big 3” haven’t manufactured anything with a flat tappet cam in nearly 20 years, and thus, the EPA has come down on the oil companies to reduce the good stuff in their oils such as zinc, sulfer, etc. (These are the things that help a flat tappet cam and lifter combination live) They are, however, hard on catalytic converters, and since the EPA doesn’t see the necessity in keeping it since none of the newer cars need it, well, it’s out. We have to find ways to combat this. The nitriding of the cam is a vital ingredient in the longevity of its life.

More to come on this story. Anyone reading this? Please leave a comment.

You know I’m reading! :) Very informative story. You MUST post that vapor vid. Sounds kind of cool.

Interesting stuff about nitriding cams.

Dude! It’s not that cool! (funny, but not cool!) I had to find out the hard way that gasoline wipes off sunblock!

Interesting info. I wonder if the cam builders are gonna start selling more cams treated or adapted for these new oils?

I just spent $50 on some zinc additive for my cars.

Just a little FYI Shell Rotella 15/40 for diesels still has all the additives the old oil had due to most diesel engines are still flat tappet, also works great for break-in oil

I’ll vouch for Pike, it’s funny at first but that wares out quick when you’re trying to play catch up with a bunch of racing vintage roadsters through the scenic routes of Arizona.

Thanks Jeff. I’ve heard the same thing. The additives for normal oil are pricey too. I have a friend who sells Amsoil. Gonna check on that. I have it in my daily now. $40 for oil and filter, but it’s good for 25,000 miles!

seriously??? To sacrifice cam overlap and therefore hp just not to get sprayed? Sounds like a bandaid to me. I’m a motorcycle engine builder and I’ll tell you that those stacks will only resonate correctly at a rpm waaaaaay higher than you’ll ever rap that 2.3 out to. Meaning….. go with longer stacks, there will be no screwing with harmonics because your stacks are way off in the first place and the benefit is you wont get sprayed.

The stacks are only part of the harmonics equation. Runner length and diameter are also important. To get the performance I wanted at a streetable rpm with this setup the runners had to be WAY too long, so I compromised and went with what looks good.

Instead of smarting off like, “Seriously???” why not suggest a cam profile. Its easy to be an internet expert, but I’ll probably still go with the professionals that work at Ingelese and do inductions systems like this all the time and have been for years. Or maybe just stick with bike engines if you’re good at it.