Engine Doctor Prescribes More Flow for Your Smallblock Ford

Cylinder Head Innovations for 302w Heads & 351w Heads

I made an appointment with the Engine Doctor, Jon Kaase. The good doctor told me about a new set of 302w or 351w heads that are ahead of their time like morphine to a cheap bottle of whiskey.

I made an appointment with the Engine Doctor, Jon Kaase. The good doctor told me about a new set of 302w or 351w heads that are ahead of their time like morphine to a cheap bottle of whiskey.

Before we trust any doctor, it’s best to look’m up and see where they come from. Kaase, as fate would have it, is the self-described “black sheep” in a family full of actual medical professionals… Kaase, on the other hand, “…liked mechanical things from the time I was little, and I never gave it up.” Sound like anyone you know?

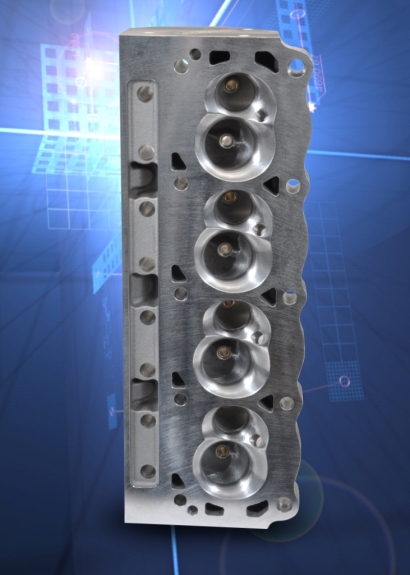

With references checking out fine, let’s learn about the new P-38 canted-valve Windsor cylinder heads. (Text and images provided by Moore Good Ink)

Small Block Ford Aluminum Heads with Better Cylinder Filling

Jon Kaase keeps his eyes peeled. Over the years, the engine builder has seen an endless string of improvements and aftermarket components visited upon the 302 Windsor heads but he was woefully aware that there were no real advancements beyond the original cylinder head configuration. He

thought he could produce castings that looked like ordinary 302w and351w heads on the outside but would be entirely different from the original blueprint on the inside. As a racer, he knew the value of stealth. But more importantly as an engine builder he knew the prime advantages of canting the valves to lean towards the center of the cylinders and so mitigate the natural shrouding effect of the cylinder wall.

Kaase designed the P-38 cylinder head primarily for the following engines:

- 302 Windsor (8.2 inch deck height, 4×3 bore/stroke, 5.095 inch rods)

- the 302’s popular, taller brother: 347 ci (over bored by 0.030 inch and stroke increased to 3.400 inch)

- the 351 Windsor (9.5 inch deck height, 4×3.5 bore/stroke, 5.960-inch rods)

- the 427-454W Sportsman-type Dart block (9.5 inch deck height with 2.750 inch Cleveland main journals).

The typical combustion chamber volume is 60-62cc.

To insure optimum cylinder filling, Kaase canted the valves at 8×4.5 degrees on the intake and 10×4 degrees on the exhaust. For those of us that aren’t savy on the cant and angle, let’s put that another way:

If you picture yourself sitting in the car with the engine in front of you, the inlet valve stems would be tilted 8 degrees back towards you and 4.5 degrees outward – towards the fenders. Similarly, the exhaust angles would be tilted forward towards the grille by 10 degrees and 4 degrees outward.

The fresh area created by the new valve angles allowed an increase in the diameter of the valve heads to 2.100 inches and 1.60 inches. Astute CNC porting would induce far superior air flow and cylinder filling compared with any conventional layout and it accomplished two things: the revised angles place the intake valve advantageously in the cylinder bore and the CNC porting is much more efficient than the original as-cast configuration. It also has the qualities of a sweeping short-turn radius (on the floor of the port) and deeper valve bowls, giving the atomized fuel a more streamlined entry to the combustion chamber.

So far Kaase has ported the P-38s to yield around 1.7hp per cu in. These engines have been mainly for use on street-strip cars and for dirt track oval race cars.

For argument’s sake, let’s assume that a 2.100-inch intake valve yields 350 cfm in a port with a given cross-sectional area. Then assume that you increase valve size to 2.200 and the port yields 360 cfm. Did you gain anything?

When increasing the valve size in a 302w head or 351w head, the larger valve flows more, but the air speed can actually be reduced. With the P-38 head, flow is increased and air speed increases too. That’s what you’re looking for… that’s the performance advantage.

Bottom line? It doesn’t pay to increase flow unless there is a simultaneous gain in air speed.

The P-38s flowed so well at 0.400-0.500 inches of valve lift that the camshaft could be tailored with 5 to 10 degrees less duration, resulting in smoother idle and better low-end manners. As such, the Kaase heads favor camshafts with close lobe centers that tend to produce more power.

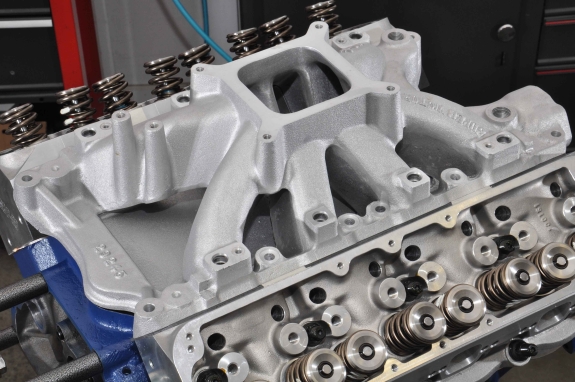

On pump fuel and with barely 9.0:1 compression ratio, a modest mechanical roller camshaft, and an Edelbrock Victor Jr. intake manifold, the Kaase 302 easily produces 500 HP at around 7,500 rpm. At the other end of the power spectrum, a Kaase-equipped 392 ci OE cylinder block sings a 650 HP song all day long and is capable of producing more than 700 HP.

Including valve covers and valve cover gaskets, the P-38 heads are supplied with larger valves, springs, seals, retainers, rocker studs and guide plates installed. Complete P-38 engines are a Kaase mainstay and are accompanied by dynamometer test results and often a video.

Along with the info how the canted and angled valves deliver more flow, at high speed… here are some details on the heads and a few assembly options:

Because the action is quicker in a mechanical roller system, greater valve spring pressure is required to maintain contact between the roller tappet and the cam lobe. Springs have an installed height of 1.950-inches and generate seat pressures of 240lb. Open pressure is 500 to 600 lbs. In contrast, seat pressure for a hydraulic roller system might be 145 to 150 lbs.

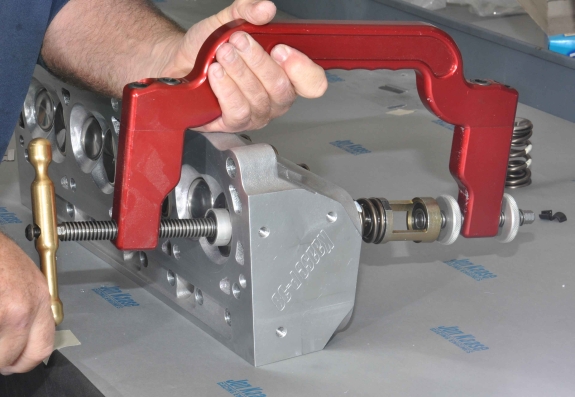

Most stud-mounted rocker arms will readily adapt to the P-38 cylinder heads but because the valves are canted, the ends of some of the fulcrum shafts may need a touch-up with a hand-grinder. Trend pushrods operate within these guide plate slots, which prevent the rockers from rotating on their axis and ensure that the ends of the rocker arms remain centered on the tips of the valves.

In addition to the P-38 head kits, Kaase concentrates on building complete engines and documents the results with dynamometer sheet and video.

Since the arc of at least one of the canted-valve rockers crashes the conventional rocker cover, Kaase’s exclusive cast aluminum versions eliminate the problem. The opportunity provided impetus to increase clamping power, so the rails on the P-38 head accept eight (rather than the usual six) fasteners.

Virtually any Windsor intake manifold, including EFI types, can complete the P-38 conversion, but the Edelbrock Super Victor and Victor Jr. have proven the most effective so far.

When Kaase ships a complete 351w engine, it will likely be accompanied by a Demon carburetor that has been flow-rate matched to displacement as well as purpose.

The P-38 cylinder heads offer “adjustable” exhaust mounting provisions, 2-inch centers for conventional tubular headers, as well as 3-inch centers that allow for even larger exhaust ports.

Kaase builds most of his crate engines with Diamond forged pistons that have been engineered for the application. If conventional pistons are used, they’ll require a small valve relief (no more than 0.125-inch at the outer edge) to accommodate the angle of the intake valve. This is a simple fly-cut operation accomplished by a hand drill.

This is Kaase: the Pro Stock engine master who achieved a remarkable 1.7ft-lb torque per cu in (103ft-lb/liter)

For more info, including pricing and complete engine options, visit JonKaaseRacingEngines.com or to dig in on the flow numbers, go directly to P-38 Flow Test Results

And finally… to see more of the good doctor’s handwork, check out the pure insanity prescribed for Steve Strope and his Pure Vision crew. It’s the Boss 502 known as the “Boss 9” pushing 805 HP in this 1969 Mustang Fastback.

Source

Jon Kaase Racing Engines

(770) 307-0241

www.JonKaaseRacingEngines.com

Thanks for running this story.

Though we made some alterations to the internals of the ports—the cross-sectional area and the chamber entries—the main changes in the P-38 cylinder heads are the canting of the valves. This concept moves the valve heads away from the cylinder walls and succeeds in directing most of the air flow into the middle of cylinders. It also allowed us to increase the valve sizes. Jon

thank you for producing these excellent cylinder heads…i’m currently saving to purchase a pair…

302 roller cammed

encouraged to friends to also purchase…351 w & 302